Description

9mm/.38 Super

MARK 7 APEX 10

NOTE: NO SALES OF MARK 7 ITEMS

OUTSIDE OF THE USA.

Comes Standard with:

- All new 11″ High Speed Case Feeder

- Lyman Stainless Steel Pro Hold Down Die included

- Mechanical Powder Measure

- Standard Priming with all New Shuttle Disk Delivery System – Small/large primer conversion included

- Double Guide Rod support for the tool head creates more stability

Key Features:

- Upgradeable with Mark 7 Autodrive and sensors

- Smooth Ergonomic Ambidextrous Handle

- Fully supported – Mark 7 community and technical help included

- Supports one-pass processing and loading

- Works with new and fired brass

- Precision CNC machined aluminum and steel

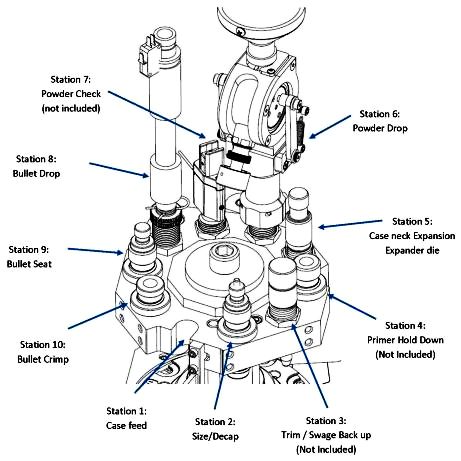

10 Station Manual Loading Machine

A massive, robust 10-station cast iron tool head which allows you to have it all:

Station 1: Case feeding

Station 2: Sizing and decapping

Station 3: Swage/Case trim

Station 4: Primer seat with hold down

Station 5: Case flare/neck expansion

Station 6: Powder drop

Station 7: Powder check

Station 8: Bullet Dropper

Station 9: Seating

Station 10: Crimping

The above is just one possible set-up. The 10 station tool head offers a large variety of options for all your reloading and case processing needs.

- All New Large capacity, fast feeding case collator

- Ergonomically designed operating handle can be assembled for right or left-hand use

- 11″ Case Feeder with variable speed motor

- Mechanical Powder Measure

- Shuttle Disk Stacked Priming System

- Supports one-pass rifle/pistol processing and loading

- Works with new AND fired brass

- Precision CNC machined aluminum and steel

- Upgradeable with Mark 7 Autodrives and sensors

- Fully supported – Mark 7 community and technical help included

- Double Guide Rod support for the tool head for more stability

- A large assortment of accessories, upgrades and sensors are available. Upgradeability

DOUBLE GUIDE ROD SUPPORT FOR THE TOOL HEAD CREATES MORE STABILITY

Â

CNC MACHINED AND PRECISION FIT FOR SMOOTH OPERATION

Â

SHUTTLE DISK STACKED PRIMING SYSTEM

Â

ERGONOMIC

HANDLE

The Apex10 can easily be upgraded with the following options at any point:

- Autodrive

- Primer Express Electronic Oscillating Primer System

- Digital Powder Measure (only with Autodrive)

- Digital Sensors (only with Autodrive)

- Machine caliber conversion kits that include everything required to convert the press from one caliber to another

- Trimmer kit for rifle processing

PLEASE NOTE: Hold Down Die is included, but additional dies and bullet feeder are not included with the Apex10 and must be purchased separately.

APEX 10 Recommended Tool Head Die Positions

Press core dimensions are: 18″ tall x 15″ wide x 11″ deep (45.7cm x 38.1cm x 27.9cm)

Machine weight: 60lbs (15.9kg)

Reviews

There are no reviews yet.