Have a Question?

September 2012

You can subscribe to this Newsletter if you sign up for an account with Titan Reloading.

CLICK HEAR TO REGISTER AN ACCOUNT

CLICK HERE To browse an archive of past newsletters.

SEPTEMBER 2012 NEWSLETTER

SEPTEMBER 2012 NEWSLETTER

Our thoughts and prayers go out to all our friends on the gulf coast. This too will pass, one day at a time. What I remember most about seven years ago is the incredible resolve of you folks down there, and how together you all went to work at rebuilding. Truly an inspiration and first class example of the American spirit. You are in our hearts.

Well, Robin and I went and did it! We leased a unit in our local strip mall. Titan Reloading will have a store front and showroom in the very near future. We will be moving our current operations first and I will keep you posted on the opening of our showroom. This will not interfere with our normal service and support. THANKS, to all of you, for making this a reality.

660 Grand Ave., Hartford, Wisconsin

Have a safe and relaxing Labor Day! You know where we will be.

We are truely enjoying all the friends we have made through Titan Reloading and look forward to many more. Feel free to contact us. Service and Support is our top priority. As always, you will find many answers to questions in the "FAQ" and "Help Videos" areas of our website www.titanreloading.com

Dennis / Titan Reloading

FEATURED PRODUCT:

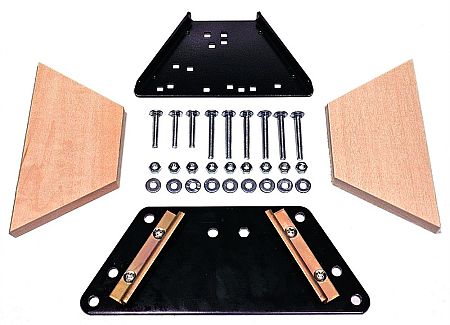

LEE BENCH PLATE SYSTEM

Includes 3 base blocks; one steel base block drilled to fit all current Lee presses and two wood base blocks. Special elevator bolt hardware included. Powder coated, thick steel mounts quickly and securely to any bench or tabletop. Wide steel plate distributes load, adding rigidity to the lightest bench top.

The Lee Bench Plate is the perfect accessory for the reloader looking to be able to quickly change between presses on their reloading bench.

Material: Steel Mounting Plate, One Steel Base Block and Two Wooden Base Blocks. The Steel Base Block has been pre-drilled with all mounting holes for Lee reloading equipment.

INSIGHT OF THE MONTH:

Crushed Cases

While there can be many reasons for a case to be crushed in the reloading process, there are primarily two.

The first is that the bullet seating die is not set properly. If the crimp shoulder is set too deeply, the case is crimped before the bottom of the press stroke is achieved. Once the bullet is seated, additional pressure pushes the already heavily crimped case into the die further resulting in a crushed case. This is a common occurence with thin and long case necks such as the 30-30 Winchester or long pistol rounds such as the .357 Magnum. Be sure to set the die per instructions.

This is a clever way to set the Bullet Seating Die quickly. The trick is to set the bullet seating depth first, then the crimp. This is done as follows; With an empty, sized case in the shell holder, hold the ram at the top of its stroke. Turn the bullet seating die body down over the case until you feel it come to a stop. This will be when the case mouth contacts the crimp shoulder inside the die. Mark this position by turning the lock ring down against the turret or press frame. Now adjust your bullet seating depth. Once you have the bullet seated to the desired depth, back the bullet seater adjuster out about 1 turn. Now turn the bullet seating die body in to apply the desired crimp. Once this is established, hold the ram at the top of its stroke and spin the bullet seater adjuster down until it stops. It is a good idea to carry this out with an empty case, so that after you have seated the bullet, you have a perfectly safe "dummy" cartridge (or gauge) to repetitively set seating depth and crimp on future occasions. Once you have this "dummy" gauge, all you have to do is place it in the shell holder, raise the ram to the top of its stroke, turn the bullet seating body down until it stops, and then turn the bullet seating depth adjuster in until it stops. Since the crimp and the seating depth were already set, the die will return to very close to the same settings.

The second reason is generally associated with the Lee Collet Dies. If the collet in the die has been collapsed, the case neck can not clearly enter the collet area. This results in a crushed and/or buckled case. This can be avoided by not operating the die without a case in it. If this happens, it is necessary to remove the collet and pry the collet leaves back so that they stay apart when inserted back into the die. The ID of the die body will cause the leaves to stay uniformity apart.