Have a Question?

February 2012

You can subscribe to this Newsletter if you sign up for an account with Titan Reloading.

CLICK HEAR TO REGISTER AN ACCOUNT

CLICK HERE To browse an archive of past newsletters.

FEBRUARY 2012 NEWSLETTER

FEBRUARY 2012 NEWSLETTER

Robin and I are "Steady as she goes" right now and looking forward to the Super Bowl. Our "Green and Gold" was knocked out early but the playoffs have been great this year. Good Luck to the Giants, Patriots and their fans. The days are growing steadily longer so we are on the right side of winter and soon, "Play Ball !" will be heard across this land. As for that groundhog this Thursday I recommend he go fly a kite, 'cause lookin' up will fix his shadow problem.

We are truely enjoying all the friends we have made through Titan Reloading and look forward to many more. Feel free to contact us. Service and Support is our top priority. I have a day job so the best time to call for support is between 6-10 PM CST. I am able to answer emails throughout the day. Robin can take your service calls daily and will pass any support questions she can't answer on to me. As always, you will find many answers to questions in the "FAQ" and "Help Videos" areas of our website www.titanreloading.com

Dennis / Titan Reloading

FEATURED PRODUCT:

Lee Reloading Stand

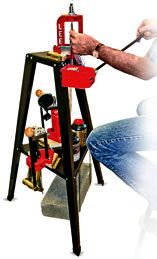

Introducing the Lee Reloading Stand, perfect for the reloader with limited working space, an overwhelmed workbench, or someone looking for solution to portable reloading needs. The sturdy powder coated steel stand places your press at the perfect counter stool or standing height of 39". The 10 inch triangular steel top plate uses the Patented quick change Lee Bench Plate system. The stand is 26" wide by 24" deep so it does not require a lot of room.

There’s more, the reloading stand includes a sturdy steel shelf with two bench plate receivers that will neatly and securely store your extra presses or mountable accessories. Included with the stand is one storage bin for component or tool storage, which clips onto the steel bin bracket provided with the stand. Each leg has eight mounting holes that allow you to accessorize your stand with a multitude of bins, shelves or accessory die racks. Includes drawing to customize and make your own extended work surface. This reloading stand is perfect for the apartment-dweller or anyone who is limited on space.

: Fits all Lee metallic presses (Fasteners for mounting one press are included).

: Powder-Coated Steel

: Comes with one storage bin and bracket, the top plate, the bottom shelf, 1 drilled wood block, complete fastener set for top plate and bottom shelf and two steel concrete block hangers.

NOTE: The press, 2 bottom shelf wood blocks and concrete block shown in the picture are not included. Concrete block is necessary for safe, stable operation. Obtain one at any building supply or home center.

INSIGHT OF THE MONTH:

Cast Bullet Leading

A clue to what is causing the leading is where the leading first begins to appear. If it appears near the chamber, chances are that bullet diameter or hardness are the cause.

A diameter too small and/or too hard an alloy will allow high pressure gas to leak past the bullet, which erodes the bullet and leaves leading near the chamber.

If the leading first appears on the leading edge of the rifling (if you imagine the bullet being pushed through the barrel, you will note that one edge of the rifling does most of the work of imparting a spin to the bullet. This is the edge you see when you look through the barrel from the breech end) the bullet might be too soft, and/or the velocity too high.

A good rule of thumb for maximum velocities when using liquid alox is 1400 feet per second for plain base bullets and 2200 feet per second when using gas check bullets. Bore conditions will require you increase or decrease this velocity slightly to prevent leading.

If the leading appears in the second half of the barrel, the bullet is running out of lube. You should see a star shaped pattern of lube accumulate on the muzzle. This is an indication that there is a little excess lube.