Have a Question?

April 2024

RELOAD WITH CONFIDENCE!

What’s Your TITAN Advantage?….WE RELOAD!

***Your Reloading Specialists***

It’s no wonder that the Harley-Davidson motorcycle was invented right here in Milwaukee Wisconsin? With only a few days since early December that temperatures have been above freezing and there are scooters out and about everywhere. I can tell by listening to the birds in the morning that summer won’t be too much longer…..all is GOOD!

We are truly enjoying all the friends we have made through Titan Reloading and look forward to many more. Feel free to contact us. When possible, please email us rather than call. Due to our limited phone system and staff we are able to respond to your questions quicker via email. Please include your full name or order ID number with any order inquiries. Service and Support is our top priority. As always, you will find many answers to questions in the “FAQ” and “Help Videos” areas of our website www.titanreloading.com . Check us out on YouTube .

Dennis / Titan Reloading

FEATURED PRODUCT:

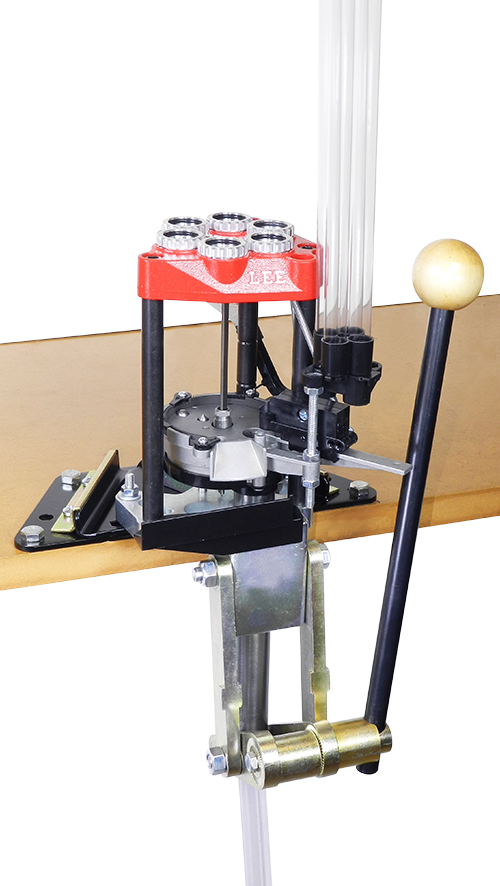

Lee Six Pack Pro

The culmination of nearly 40 years of progressive press design and production. Years of comments and suggestions have been incorporated into this new press.

Includes: Six Pack Reloading Press, bin and bracket and universal 4 tube case feed magazine.

Reloading dies, Shell plate, Auto Drum Powder Measure and rifle short or long charging dies sold separately.

Features:

Six stations allow any brand of die be used — in line bullet feed dies, powder check dies and such.

Simple and reliable automatic indexing — just one moving part, replaceable in seconds, no tools required and never requires adjustment.

Stroke and clearance sufficient for largest magnum rifle cases. Uses the same all steel linkage found on our Classic Cast 50 BMG press.

Massive 28.4mm ram glides through 82 mm of solid steel giving the ram over 7300 mm2 of solid support.

Spent primer tube collects dirty, gritty spent primers.

All dies securely fastened in the upper die carrier with the LEE Breech lock quick die change system. No more turret or tool head to replace or move during use.

Automatic priming system – simple, reliable and safe with any brand or size of primer. Primes at the bottom of stroke so all six stations are available for operations.

Automatic case inserter works with any case. Cases can be manually fed through the convenient loading port.

Easy to set case retainers on every station. No springs, plugs or buttons to loose or tinker with.

Cartridge changeover in seconds, including primer size with no adjustments.

Automatic case ejector reliably whisks away your completed round to the ammo bin. Press includes combination tool rack, bin bracket, along with free ammo bin.

Product information:

| Base material | Steel |

| Columns material | Steel |

| Ram | Steel |

| Ram diameter | Over 1″ |

| Linkage | Steel |

| Shell plate carrier material | Steel |

| Shell plate carrier cover material | Zamak 5 Zinc |

| Tool head material | Aluminum |

| Die size accepted | 7/8″ x 14 |

| Number of die mounting holes | 6 |

| Breech Lock Quick Change bushings | Yes |

| Priming feature | Yes, no primer brand restriciton |

| Spent primer collection tube | Yes |

| Maximum COAL Limit | 3.340″ |

| Country of origin | Proudly made in USA |

INSIGHT OF THE MONTH:

The Economics of Reloading: Analyzing Cost Savings Over Time

In the world of shooting sports and hunting, the debate between purchasing factory ammunition and reloading your own is as old as the practice itself. With the rising costs of ammunition and the growing interest in custom loads, more shooters are turning towards reloading as a cost-effective and satisfying hobby.

In this article, our experts at Titan Reloading will compare the costs and benefits of reloading supplies vs factory-made ammunition to help you determine how much, and how quickly, you can save.

The Basics of Reloading Supplies

Understanding the costs associated with reloading begins with a comprehensive look at the necessary supplies. Reloading requires an initial investment in equipment and materials, including:

● Reloading Press: The cornerstone tool for any reloader, available in single-stage, turret, and progressive models.

● Dies: Caliber-specific tools that resize the brass, remove the spent primer, and seat the new bullet.

After this, you’ll incur per-round costs:

● Powder: Propellant for the bullet, which must be measured precisely for safety and performance.

● Primers: Small but critical components that ignite the powder charge.

● Bullets: Projectiles, available in various weights and designs for different purposes.

● Brass Casings: The reusable shell that holds the bullet, powder, and primer together.

While this list of supplies might be daunting, let’s take a look at how they compare to factory ammunition costs in the long run.

The Costs of Reloading vs Factory Ammo

While the immediate investment of reloading equipment can serve as a barrier, the reloader who invests in bulk components can often see the cost per round drop below that of factory ammo.

Unlike factory ammunition, where you pay for each round, reloading supplies can be purchased in bulk, at a lower per-unit cost. Additionally, brass casings can be reused multiple times, further reducing expenses.

The savings extend beyond just the price per round. Reloading allows shooters to customize their loads to match their specific needs, potentially leading to better performance and accuracy without the premium price tag of specialty factory ammunition. This aspect, while not directly a part of the cost analysis, adds value to the practice of reloading.

The Long-Term Cost Savings Analysis

To truly appreciate the economic benefits of reloading, you’ll have to consider the long-term savings, especially for frequent shooters. Over time, the initial cost of purchasing reloading equipment is amortized over thousands of rounds, significantly lowering the average cost per round compared to factory ammo.

Frequent shooters, who expend large quantities of ammunition, benefit the most from reloading. Not only do they save money with each round, but they also gain the flexibility to produce custom ammunition tailored to their shooting preferences.

For those contemplating the switch to reloading for economic reasons, it’s crucial to project your shooting habits and ammunition usage over several years. By doing so, you can calculate the break-even point.

For example, high-quality equipment might cost you about $600, and each bullet might save you $0.20 per round. At this rate, you’ll break even at about 3000 rounds, improving your cost-efficiency and quality in each round thereafter. Beyond the economic benefits, reloading often becomes an enjoyable hobby, adding to the list of long-term benefits.

Getting Started with Quality Reloading Supplies

To maximize your cost savings with reloading, it’s important to invest in high-quality reloading supplies. The right equipment can save you time and money in the long run, while also helping you improve the quality of your ammunition.

Fortunately, Titan Reloading provides the reloading resources and supplies you’ll need to create better bullets at a lower cost. Whether you’re a seasoned reloader or just starting out, our comprehensive catalog has everything you’ll need to start saving on ammunition.

With Titan Reloading, you’re choosing a trusted provider of top-tier reloading supplies. Discover our exceptional range of reloading supplies by visiting our showroom, conveniently located at 994 W. Sumner St., Hartford, Wisconsin, or contact us today to find the best reloading supplies for your needs. Tap into the Titan Advantage today and let precision guide your reloading journey.